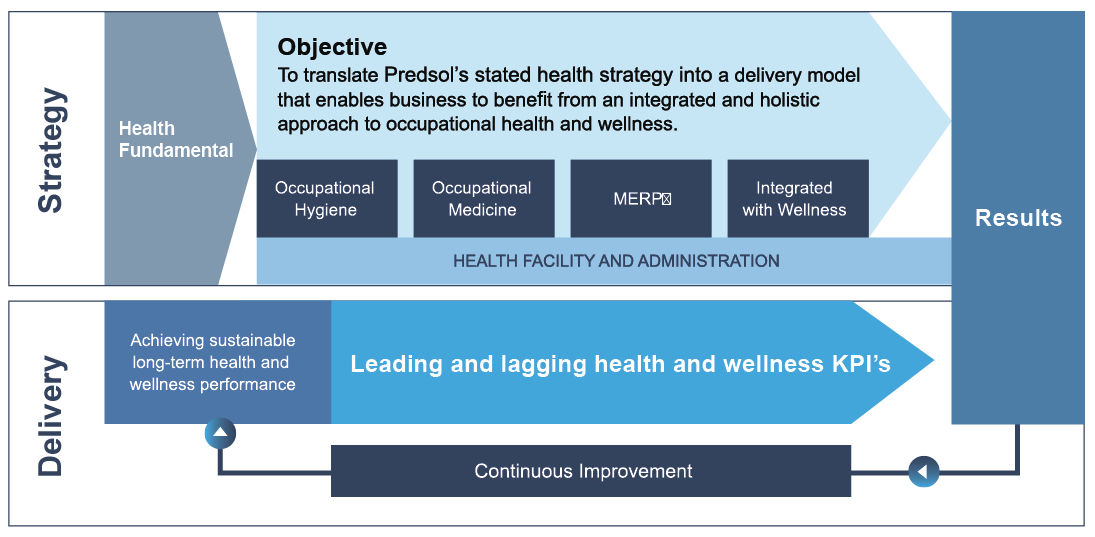

Having shaped our mindset towards delivery of highest quality, we are partnering with the Well-Known Filed Service Companies owning proven track records and tens of years of experience in industrial equipment maintenance.

Modern, field-proven service concepts and methods are integrated into our service contracts, which are adjusted to the individual needs of each customer. What’s more, our services incorporate best practices from similar projects worldwide. A clearly defined business plan aligned to your objectives describes the service policy and organization, key performance indicators and continuous improvement measures.

Predsol is here to support you with:

OPERATION & MAINTENANCE

We run the whole system in close cooperation with you in a performance-based contract.

What we can HELP YOU with?

We are YOUR one-stop shop for most of YOUR maintenance and inspection/troubleshooting scope! Our Team carries the vast amount of experience, trained and developed to deliver maintenance and inspection services as YOUR in-house maintenance team:

FULL MAINTENANCE

Our service team carries out all maintenance activities – such as preventive and corrective measures, inspections and Maintenance Management – according to clearly defined key performance indicators.

Your Rotating equipment from conventional single unit to smart and sophisticated automated skids.

- We are skilled to maintain Your Compressors & Pumps, it’s Drives and Gearboxes, as well as its’ automation components – valves, Control units, actuators, piping and etc.

- We are ready to Service and Set up Your Emergency Shut Down Systems.

- You can Rely on Our Experience

- Whether YOU are in Gas, Oil, Chemical or Water service

- Whether Your equipment is set up to be operated in Hazardous Zone or Not

Note: For Powerpacks maintenance please refer to - Automated Skid.

Our first step in developing trust and building long-term relationship with YOU:

- Assess and / or develop equipment hierarchy

- Review and collect equipment nameplate and configuration information (where needed)

- Develop equipment maintenance plans (EMPs) for maintainable assets

- Develop maintenance/job plans, in agreed-upon format from finalized EMP

- Recommend any Predictive Maintenance (PdM) job plans where applicable

- Review with YOU and finalize maintenance /job plans

- Submit finalized maintenance job plans

Your Torque Drives and wrenches, whether they are Pneumatically, Hydraulically or electrically powered.

If You own the Heavy Machinery, we can keep them running

- We are skilled to maintain Your Forklifts, Side Loaders, Overhead and Mobile Cranes.

MAINTENANCE SUPERVISION

Our team works together with your team in a blended maintenance organization.